Код продукта:4Р СБС

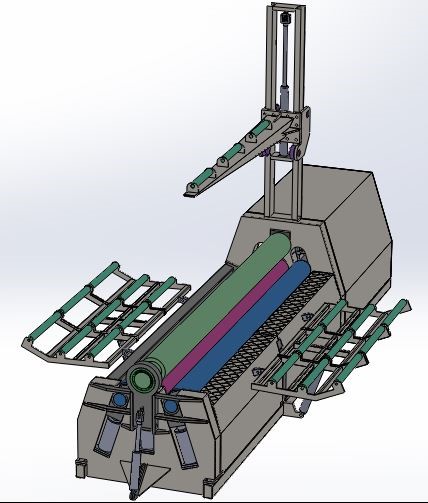

Он используется для гибки тонкого или толстого листового металла в виде полного круга, полукруга, конуса или радиуса с ожидаемым уклоном.

- Главная

- PRODUCTS

- СТАНОК ДЛЯ ГИБКИ ПЛИТЫ

- 4-ЦИЛИНДРОВАЯ ПРОКЛАДОЧНО-ГИБОЧНАЯ МАШИНА

4-ЦИЛИНДРОВАЯ ПРОКЛАДОЧНО-ГИБОЧНАЯ МАШИНА

4-ЦИЛИНДРОВАЯ ПРОКЛАДОЧНО-ГИБОЧНАЯ МАШИНА

| Model | Working Length | Rolling Thickness | Prebending Thickness | Min.Rolling Diameter |

Dia of Top Cylinder |

Dia of Down Cylinder |

Dia of Side Cylinders |

Motor Power |

Dimensions(L-W-H) |

Weight |

| mm | mm | mm | ø mm | ø mm | ø mm | ø mm | Kw | mm | kg | |

| 4R SBS 2008 | 2050 | 8 | 6 | Dia of Top x2 Top rollerx2 | 190 | 170 | 150 | 7,5 | 4600X1300X1300 | 3500 |

| 4R SBS 2010 | 2050 | 10 | 8 | 210 | 190 | 170 | 11 | 4600X1400X1400 | 4500 | |

| 4R SBS 2013 | 2050 | 13 | 10 | 230 | 210 | 190 | 11 | 5000X1500X1500 | 5000 | |

| 4R SBS 2016 | 2050 | 16 | 13 | 280 | 250 | 220 | 15 | 5000X1700X1700 | 6000 | |

| 4R SBS 2020 | 2050 | 20 | 16 |

Üst topx3 Top rollerx3 |

310 | 270 | 240 | 19 | 5000X1850X1850 | 7000 |

| 4R SBS 2025 | 2050 | 25 | 20 | 330 | 300 | 250 | 19 | 5000X1900X1900 | 8500 | |

| 4R SBS 2030 | 2050 | 30 | 25 | 360 | 330 | 260 | 26 | 5000X2000X2000 | 11500 | |

| 4R SBS 2040 | 2050 | 40 | 30 | 390 | 360 | 300 | 30 | 5000X2200X2200 | 16000 | |

| 4R SBS 2045 | 2050 | 45 | 35 | Dia of Top x4 Top rollerx4 | 420 | 390 | 330 | 30 | 5000X2300X2300 | 18000 |

| 4R SBS 2050 | 2050 | 50 | 40 | 460 | 420 | 380 | 37 | 5500X2500X2500 | 19500 | |

| 4R SBS 2508 | 2550 | 8 | 6 | Dia of Top x2 Top rollerx2 | 210 | 190 | 170 | 11 | 5100X1400X1400 | 5000 |

| 4R SBS 2510 | 2550 | 10 | 8 | 230 | 210 | 190 | 11 | 5500X1500X1500 | 5500 | |

| 4R SBS 2513 | 2550 | 13 | 10 | 280 | 250 | 220 | 15 | 5500X1700X1700 | 7000 | |

| 4R SBS 2516 | 2550 | 16 | 13 | 310 | 270 | 240 | 19 | 5500X1850X1850 | 9500 | |

| 4R SBS 2520 | 2550 | 20 | 16 | Dia of Top x3 Top rollerx3 | 330 | 300 | 250 | 19 | 5500X1900X1900 | 13000 |

| 4R SBS 2525 | 2550 | 25 | 20 | 360 | 330 | 260 | 26 | 5500X2000X2000 | 16000 | |

| 4R SBS 2530 | 2550 | 30 | 25 | 390 | 360 | 300 | 30 | 5500X2200X2200 | 18000 | |

| 4R SBS 2540 | 2550 | 40 | 30 | Üst topx4 Top rollerx4 | 420 | 390 | 330 | 30 | 5500X2300X2300 | 20000 |

| 4R SBS 2545 | 2550 | 45 | 35 | 460 | 420 | 370 | 37 | 6000X2500X2500 | 22500 | |

| 4R SBS 2550 | 2550 | 50 | 40 | 510 | 460 | 400 | 45 | 6000X2650X2650 | 31000 | |

| 4R SBS 3006 | 3100 | 6 | 4 | Dia of Top 2 Top rollerx2 | 210 | 190 | 170 | 11 | 5600X1400X1400 | 5300 |

| 4R SBS 3008 | 3100 | 8 | 6 | 230 | 210 | 190 | 11 | 6000X1500X1500 | 6000 | |

| 4R SBS 3010 | 3100 | 10 | 8 | 280 | 250 | 220 | 15 | 6000X1700X1700 | 7000 | |

| 4R SBS 3013 | 3100 | 13 | 10 | 310 | 270 | 240 | 19 | 6000X1850X1850 | 8500 | |

| 4R SBS 3016 | 3100 | 16 | 13 | Üst topx3 Top rollerx3 | 330 | 300 | 250 | 19 | 6000X1900X1900 | 10500 |

| 4R SBS 3020 | 3100 | 20 | 16 | 360 | 330 | 260 | 26 | 6000X2000X2000 | 12000 | |

| 4R SBS 3025 | 3100 | 25 | 20 | 390 | 360 | 300 | 30 | 6000X2200X2200 | 17000 | |

| 4R SBS 3030 | 3100 | 30 | 25 | Dia of Top x4 Top rollerx4 | 420 | 390 | 330 | 30 | 6000X2300X2300 | 22500 |

| 4R SBS 3040 | 3100 | 40 | 30 | 460 | 420 | 370 | 37 | 6500X2500X2500 | 26000 | |

| 4R SBS 3045 | 3100 | 45 | 35 | 510 | 460 | 400 | 45 | 6500X2650X2650 | 33000 | |

| 4R SBS 3050 | 3100 | 50 | 40 | 550 | 510 | 450 | 52 | 6500X2800X2800 | 40000 | |

| 4R SBS 4006 | 4100 | 6 | 4 | Dia of Top x2 Top rollerx2 | 270 | 230 | 210 | 19 | 7000X1700X1700 | 9500 |

| 4R SBS 4008 | 4100 | 8 | 6 | 300 | 260 | 230 | 26 | 7000X1850X1850 | 11500 | |

| 4R SBS 4010 | 4100 | 10 | 8 | Üst topx3 Top rollerx3 | 330 | 300 | 250 | 26 | 7000X1900X1900 | 14000 |

| 4R SBS 4013 | 4100 | 13 | 10 | 360 | 330 | 260 | 30 | 7000X2000X2000 | 16000 | |

| 4R SBS 4016 | 4100 | 16 | 13 | 390 | 360 | 300 | 30 | 7000X2200X2200 | 20000 | |

| 4R SBS 4020 | 4100 | 20 | 16 | Üst topx4 Top rollerx4 | 420 | 390 | 330 | 37 | 7000X2300X2300 | 24000 |

| 4R SBS 4025 | 4100 | 25 | 20 | 460 | 420 | 370 | 37 | 7500X2500X2500 | 34000 | |

| 4R SBS 4030 | 4100 | 30 | 25 | 510 | 460 | 400 | 45 | 7500X2650X2650 | 38000 | |

| 4R SBS 4040 | 4100 | 40 | 30 | 550 | 510 | 450 | 52 | 7500X2800X2800 | 48000 | |

| 4R SBS 6006 | 6100 | 6 | 4 | Dia of Topx3 Top rollerx3 | 330 | 300 | 250 | 26 | 9000X1900X1900 | 18000 |

| 4R SBS 6008 | 6100 | 8 | 6 | 360 | 330 | 260 | 30 | 9000X2000X2000 | 22500 | |

| 4R SBS 6010 | 6100 | 10 | 8 | 390 | 360 | 300 | 30 | 9000X2200X2200 | 27000 | |

| 4R SBS 6013 | 6100 | 13 | 10 | Dia of Topx4 Top rollerx4 | 420 | 390 | 330 | 37 | 9000X2300X2300 | 32000 |

| 4R SBS 6016 | 6100 | 16 | 12 | 460 | 420 | 370 | 37 | 9500X2500X2500 | 40000 | |

| 4R SBS 6020 | 6100 | 20 | 16 | 510 | 460 | 400 | 45 | 9500X2650X2650 | 48500 | |

| 4R SBS 6025 | 6100 | 25 | 20 | 550 | 510 | 450 | 52 | 9500X2800X2800 | 60000 | |

| 4R SBS 6030 | 6100 | 30 | 25 | 600 | 560 | 490 | 66 | 9500X3000X3000 | 67000 | |

| 4R SBS 6040 | 6100 | 40 | 28 | 640 | 600 | 520 | 75 | 9500X3000X3200 | 73500 |

*Sheet bending capacity calculated according to 24 kg/mm2 grade steel sheets.

*Dimensions are approximately. SBFM may change the dimensions without prior information.

Материал выравнивается между 4-мя цилиндрами. Производится предварительная гибка. После этого процесс гибки осуществляется до необходимого диаметра.

- СНГ

- СПГ

- Жидкое топливо

- Пропитание

- Автоклавы

- Реакторы

- аэронавтика и космос, баллоны высокого давления,

- Ветряная башня

- Силосы

- Верфи

- Бензиновые платформы

- оборонная промышленность

- Тяжелое оборудование

- строительство

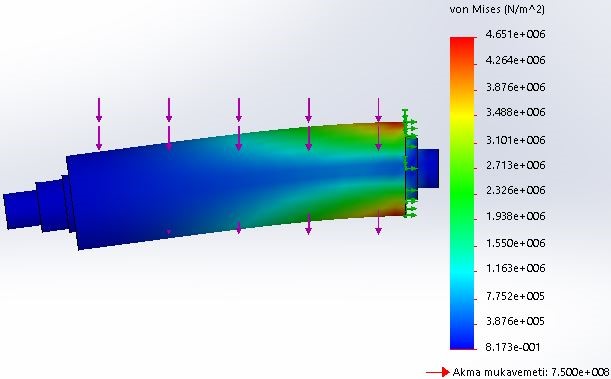

This part is the first step of machine production process and it contains making needed calculations of machines, drawing these machines on CAD programs like AutoCAD and Solidworks to see integrated productions as 3D dimension virtually and analysing machines. Currently, we have 2 Solidworks CAD program - one of them is with structurel analysis module-. Machines are designed as 2D and 3D for controlling capabilities of machines visually

Design process is not proceeding only with one person. Just in case possibility of being some mistakes or improvements, meetings are set for review of design and different options for improvements are considered by taking support of analysis program as well. Then, it is approved for passing next step of production process.

One of the steps before starting machine production is procuring necessary materials according to product tree list that is decided in design step. In this step, flat plate products, steel of shafts, brass blocks, hydraulic cylinder materials etc. are procured.

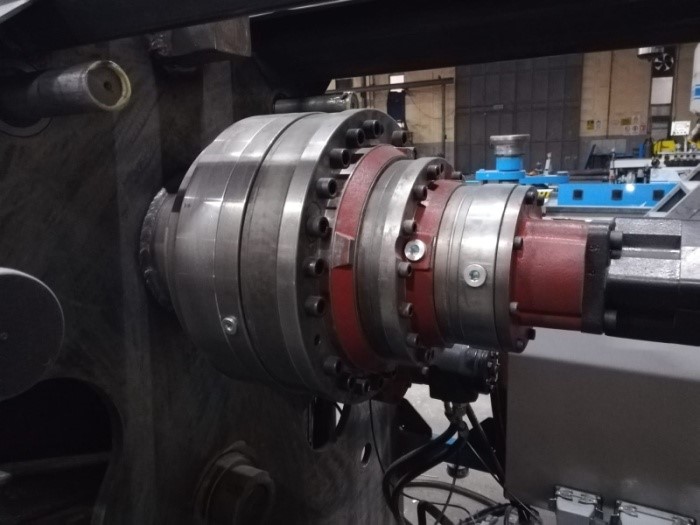

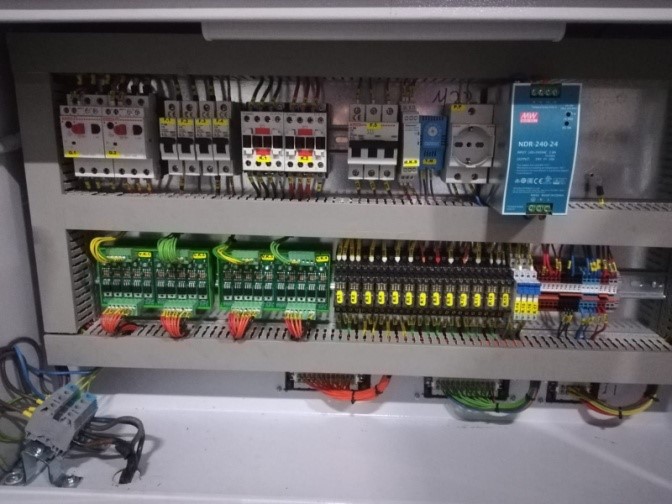

These are the components that have manufactured, have been manufacturing or procured from marketplace and ready to use in the assembly part. These components can be classified as Electrical Unit, Hydraulic Unit, Reductor, Ball Bearings etc.

In this step of the process , these kind of works are carried out ; for completed machine elements as schematically and constructionally, being taken technical drawings and forming some parts which are needed, with the aid of various cutting tools.

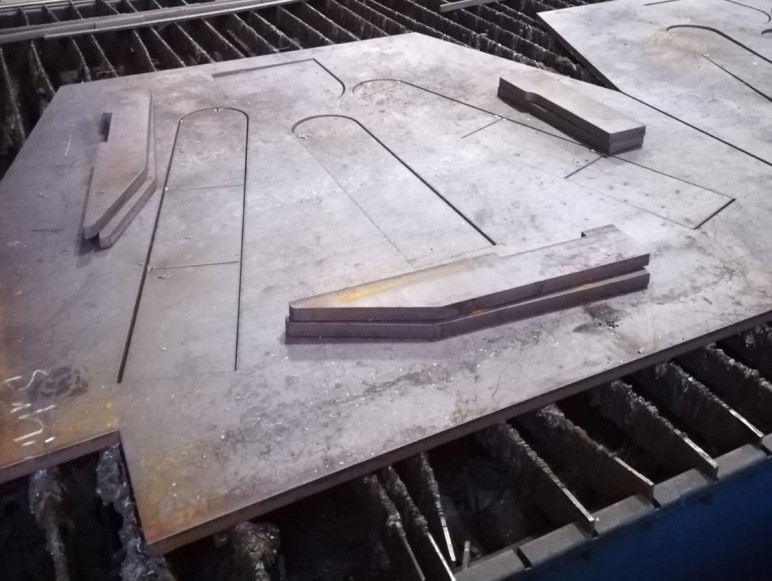

Raw materials that have been procured as sheet metal in different dimensions and specifications, are cut according to drawings that prepared in design step , by using CNC Plasma Machine.

In this step, some specified parts in the desing step are welded properly after machining or cutting step to make it ready for assembly.

This is the last step of manufacturing process and in this step, all parts are assembled. Then integrated machine is obtained.

After production of machine, another very important case that controlling the machine. So, in this step machine is tested to verify reality of datas that obtained theoritically and in virtual system. This step includes all parts of machine. Firstly, controlling is started from electrical equipment. The electric panel, valves and other electrical parts are tested. Then, movements of pistons and leakage of hydraulic oil are checked over. Finally, the material which will treated, is placed to machine properly and it is worked on material to test for general tests of machine.

After all tests are done and datas are confirmed, machine is ready for delivery.