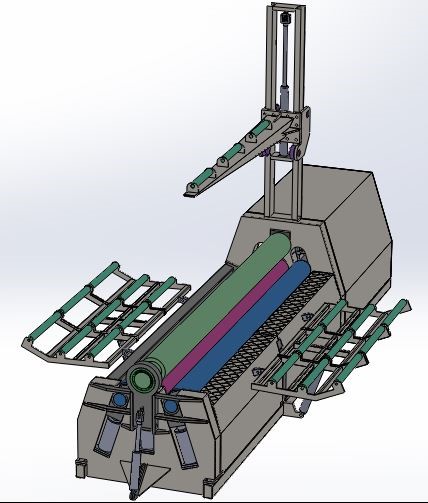

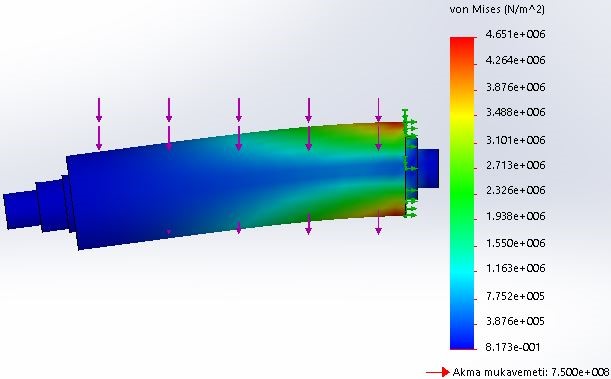

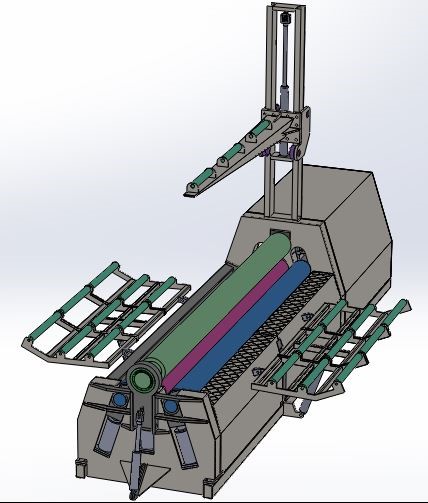

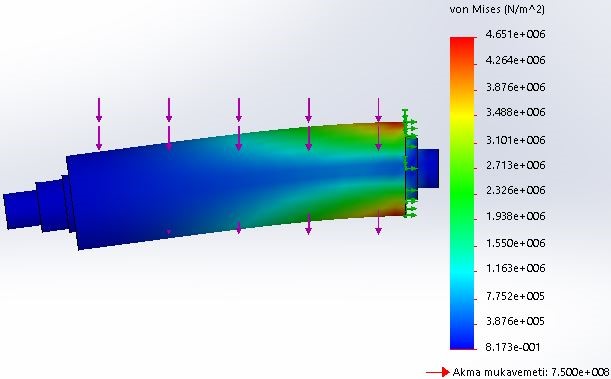

This section, which is at the very beginning of the machine production phase, is the section where the necessary calculations of the machines to be produced are made, and the integrated system is viewed in 3D in a digital environment using CAD programs such as AutoCAD and Solidworks, and various analyses are made. Currently, there are 2 Solidworks CAD programs in our company, 1 of which is with a structural analysis module. The drawings of the machines are made in 3D and 2D in a way that can be visually controlled.

Design processes do not proceed with a single person. Despite design blindness, different opinions are supported with the analysis program through in-team design review meetings, necessary improvements are made, and approval is given for the transition to the production stages.

It is one of the stages of procuring the materials that will be required according to the product tree list created in the design phase before starting the machine production. In this stage, products such as flat plate products to be used for the body, steel of the rollers, brass bearings, hydraulic cylinder materials etc. are procured.

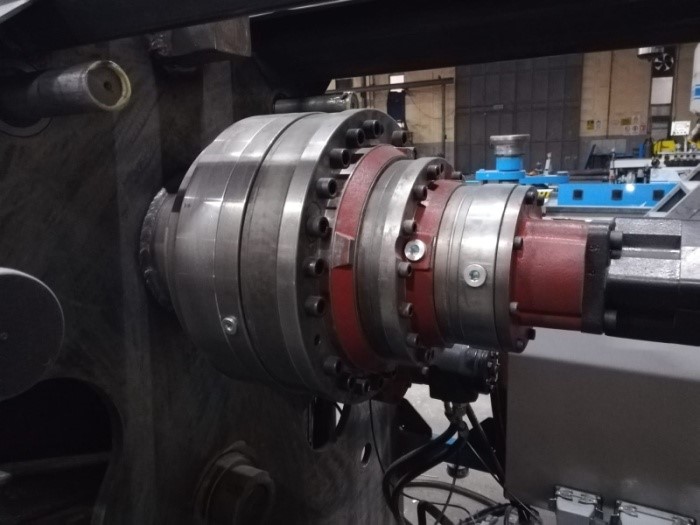

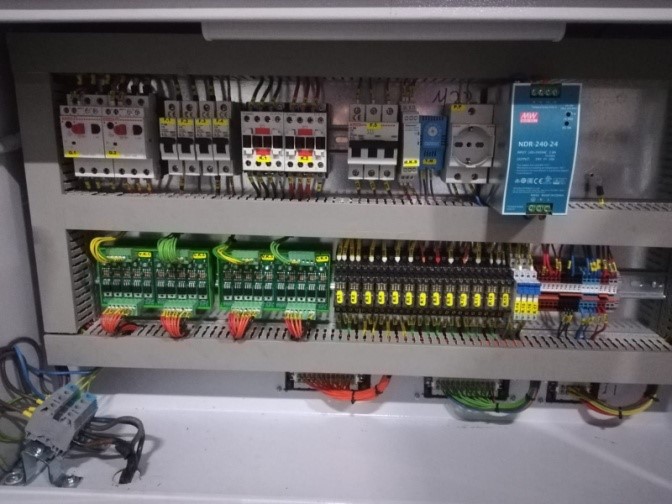

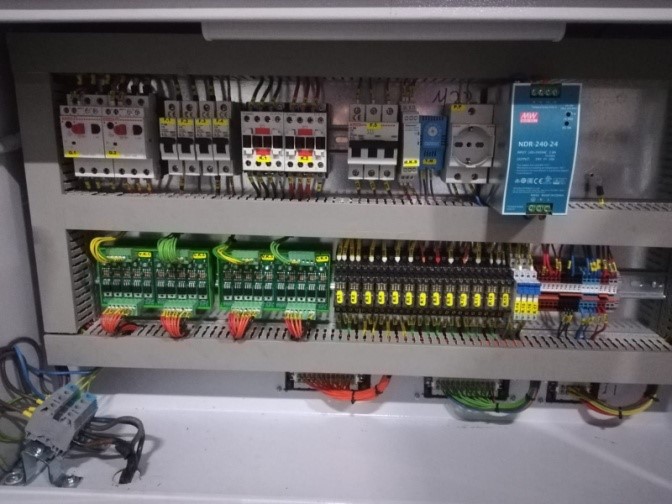

They are components that have already entered the production process and are being produced or supplied from the market and can be used later in the assembly phase. We can classify these components as Electrical Unit, Hydraulic Unit, Reducer, Bearings, etc.

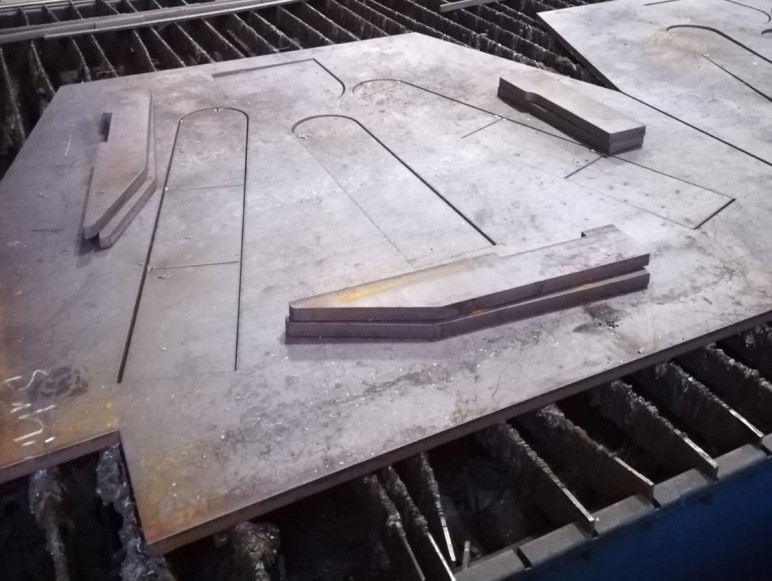

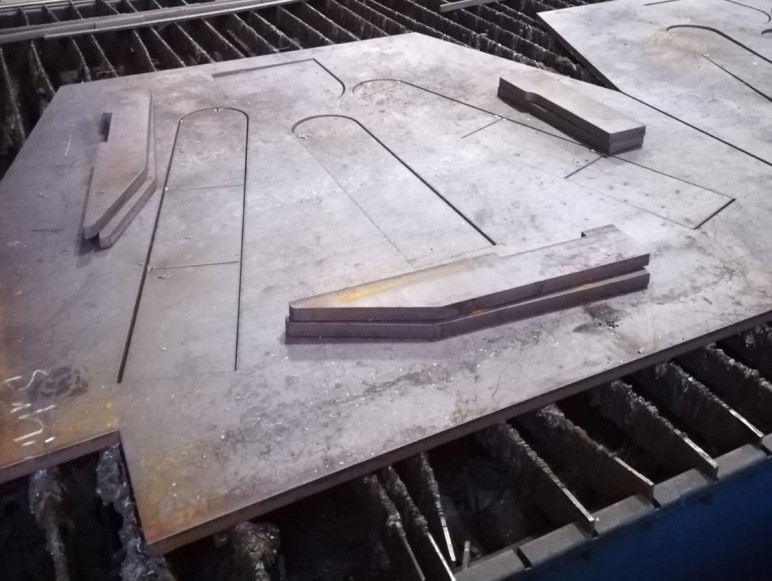

It is the stage of processing the raw materials taken as sheet metal in various thicknesses and properties in a CNC plasma machine according to the drawings prepared in the design phase.

This is the part where the parts are appropriately welded in the shapes determined in the design phase after machining or cutting to prepare them for assembly.

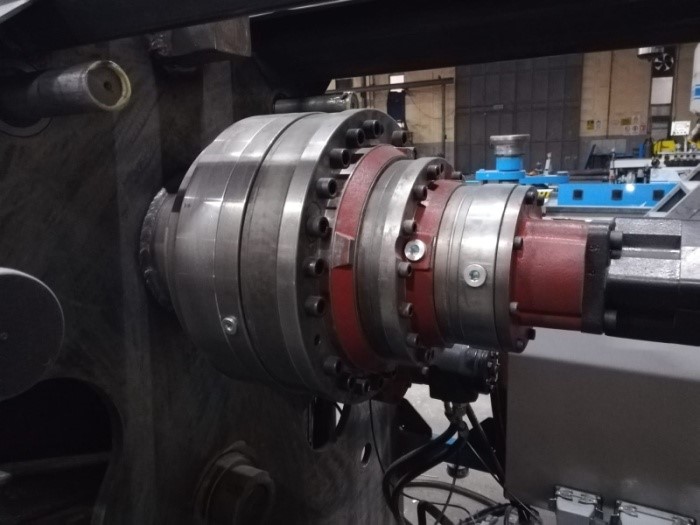

The final stage of the manufacturing process is the assembly stage, where all parts are brought together and an integrated machine is obtained.

After the machine is manufactured, as an important requirement, the testing process is carried out to support and ensure the reality of the data obtained theoretically and in the virtual system. This process generally covers all components of the machine. First of all, the control process starts with the electrical parts. Electrical parts such as whether the panel works properly, the operation of the valves, and the testing of the control panel are tested. Then, the movements of the pistons and whether there is a hydraulic oil leak are examined. As the last stage, the material to be processed is placed in the machine and the necessary operations are carried out on the material to ensure that the machine will not cause a functional problem.

After all the inspections and tests of the machine are completed and these processes yield successful results, the machine is ready for delivery.