Furnaces are the equipment where combustion mostly takes place in steam boilers. They are divided into two types: flat and corrugated. Flat ashtrays are generally preferred for low pressures, while corrugated ones are preferred for high pressures and long life.

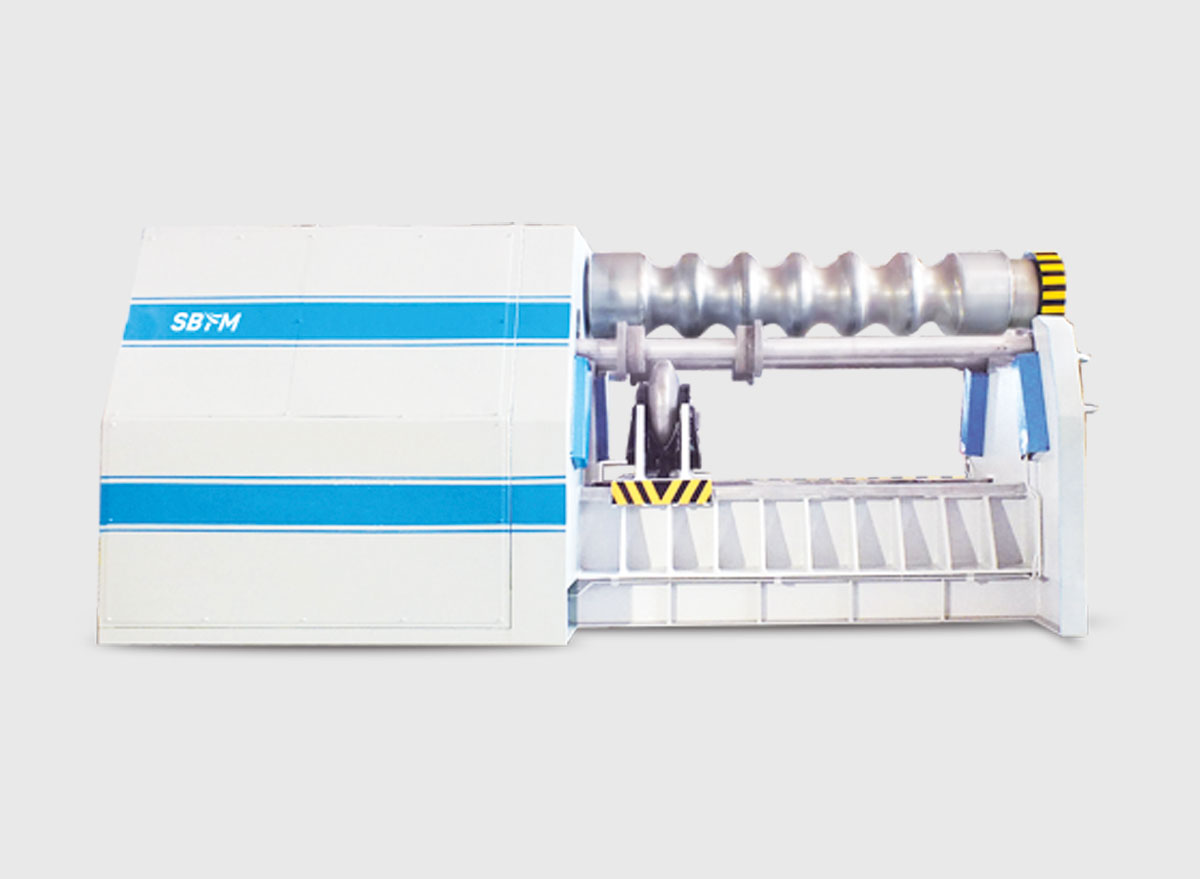

Corrugated furnace machines is an industrial tool used to increase the strength of metal parts and to obtain the desired shape. This machine, which is especially used in sheet metal bending processes, adds durability to materials such as steel. Pre-manufactured components or components procured from the market are the parts used in the assembly stage and can generally be categorized into various categories such as Electrical Units, Hydraulic Units, Gearboxes, Bearings, etc.

Corrugated furnace machines, the cylindrically bent parts are given the desired shape by rotating between the rollers to gain strength.

• Sheet bending capacity is based on steel with a yield limit of 24 kg/mm2.

• Provides more effective heating by changing the heating method

• Reduces cost while increasing efficiency.

• User and environment friendly.

In terms of strength and quality, Corrugated furnace machines offers an effective method to increase the durability of metal parts. This improves the quality and reliability of parts used in industrial applications.

Three Pass Scotch Type Steam Boilers

Three-pass scotch type steam boilers are the most widely preferred type of steam boiler for medium-sized enterprises in our country and in the world industry. These boilers are preferred in many industrial applications with their wide usage areas and unique features.

The ashpan, one of the critical components of the boiler, is usually designed as corrugated. This design prevents longitudinal elongation of the combustion cell under the influence of heat and increases the durability of the boiler by increasing the resistance to external pressure. This structure is preferred more frequently especially in large capacities and contributes to the long-lasting performance of the boiler.

Three-pass scotch type steam boilers have a wide range of applications. They are widely used in many sectors from steam turbines to steam heating systems, from chemical processes to the food industry. Especially thanks to their ability to meet sudden steam transitions, they respond quickly to the variable demands of industrial enterprises.

The advantages of these boilers include the following:

Ability to meet sudden steam withdrawals: It increases production continuity and efficiency with its ability to adapt to the variable demands of the enterprises.

Large evaporation surface and steam volume: Provides high efficiency thanks to efficient steam generation.

Corrugated and large combustion surface: Increases durability and helps the boiler to provide long-lasting performance.

Easy accessibility: Smoke pipes, steam boilers (also called infernos) and water sides are easily accessible, facilitating maintenance and repair processes.

Three-pass scotch type steam boilers ensure that industrial plants have a reliable and efficient energy source. These boilers optimize production processes and provide competitive advantage by meeting the needs of industrial enterprises with their wide usage areas and advantages.

Similarities can be drawn between the three-pass scotch-type steam boilers and the corrugated ashpan.

A corrugated furnace is a structure that captures the heat generated by the combustion of wood, coal or other fuels and uses this heat to convert water into steam. This structure works with high efficiency thanks to the piping systems surrounding the combustion chamber. The pipes allow the combustion gases to pass through multiple times, allowing more heat to be captured, leading to a more efficient energy conversion in steam production.

Similarly, three-pass scotch-type steam boilers allow combustion gases to pass through the piping systems in three different passes, resulting in higher efficiency. These boilers are also designed to maximize the heat from the combustion process. Sometimes these designs are also sometimes referred to as slotted furnace machines or roller hearth furnace machines.

From this perspective, both systems are focused on increasing the efficiency of steam production by making the best use of the heat energy of the combustion gases. Thus, there are certain similarities between three-pass scotch-type steam boilers and corrugated furnace engines.