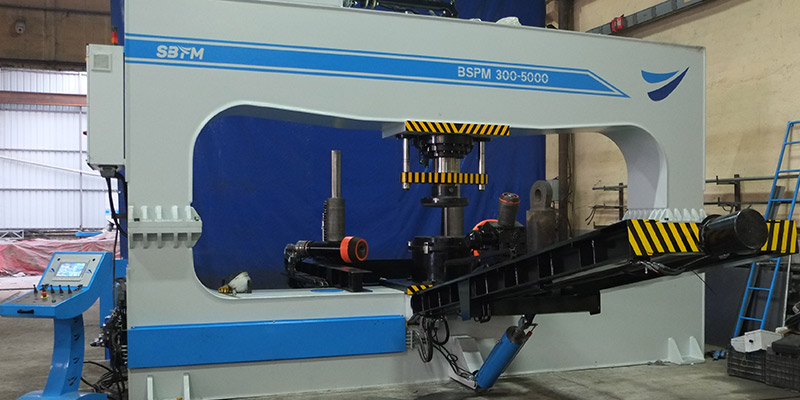

Hydraulic presses, which are used to increase the efficiency of industrial production processes and ensure occupational safety, become more useful in terms of efficient production when equipped with manipulator systems. It also offers advantages in many aspects such as reducing the error rate and cost rate. SBFM's hydraulic press machine with manipulator offers such advantages for your business. In this article of SBFM Machine, information will be given about the manipulator systems of hydraulic presses, their operation, advantages and usage areas in the industry.

What is Manipulator Systems of Hydraulic Presses?

Hydraulic presses are machines that shape materials with high pressure and perform operations such as bending, cutting and punching. Manipulator systems are integrated into the press machines and provide easy features such as automatic handling, positioning and processing of materials. Manipulators, when optimised with the processes that require a press, produce a faster, more precise and safer result.

Functioning of Systems with Manipulators

Manipulator systems, usually CNC controlled, perform the process of automatically placing and pressing the materials during the operation of the press. The functioning process of these machines, which work synchronised with the presses, consists of the following steps:

-

Material Feeding: When the manipulator is used in the machinery industry, it brings the sheet material to be shaped to the working area of the hydraulic press.

-

Positioning: The metal material is correctly placed on the press table to give the desired shape.

-

Pressing: The hydraulic system transforms the material into the desired form by applying high pressure.

-

Extraction: The manipulator removes the processed material from the press area and makes it ready for the next process. In short, systems with manipulators are very useful in terms of transporting the material to be processed from one place to another.

Advantages

Hydraulic presses with manipulator have many advantages. When we look at these advantages:

-

High Precision: Thanks to CNC systems, operations are performed with maximum accuracy.

-

Increased Productivity: Automation increases production speed and minimises human error.

-

Work Safety: Manipulators minimise hazards. Therefore, it prevents the risks that operators may encounter, thus increasing occupational safety.

-

Flexibility: Easily optimised for different material types and forming processes.

-

Cost Savings: Contributes to production by reducing workload costs.

Areas of Use

Hydraulic presses with manipulators have a wide range of applications in various industries. These areas are:

-

Automotive Industry: It is used for shaping vehicle body panels, chassis and other metal parts.

-

Aerospace Industry: It performs precise forming and assembly of aircraft components.

-

Construction Industry: Automates the production of steel structural elements and other metal parts to meet material requirements.

-

White Goods Production: It is used in the production of small and large household appliances used in homes.

-

Defence Industry: It contributes to the defence industry by facilitating the production of armour plates and other defence vehicles.