Metals, one of the basic building blocks of today's industry, have a wide range of uses in many sectors. When we look at the areas where metals, which have an indispensable role in modern industry, are used, it is frequently preferred in sectors such as construction, automotive, aviation, as they are durable materials that offer strength advantages. In this article, we will discuss the industrial use and importance of concepts such as metal sheets, metal bending, metal crimping metal bender, plate rolling, and bending-crimping, and the machines commonly used in metal forming processes as SBFM Makine.

Metal Sheets and Application Areas

Metal sheets have a wide range of uses from automotive to construction. It is especially preferred for bending materials that require strength. The production and use of sheet metal bending ofters the opportunity for high durability and flexibility.

- Automotive Industry: Used in the construction of vehicle bodies and parts.

- Construction Industry: Preferred in the production of roofs, coatings and structural components.

Metal Bending and Crimping Techniques

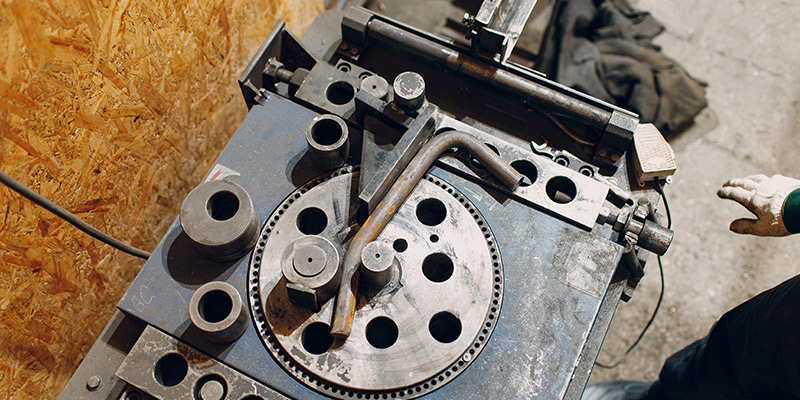

Metal bending and crimping are the methods applied to bring the plates to the desired shape with the help of technologies called sheet metal bending machines. These techniques are performed not only with a single machine but also with various machines of SBFM such as Flanging Machines, curved edge bending flanging machine, 4 and 3 roll plate sheet bending machine, ellipse bending machine, profile and pipe bending machines.

- Curving Bending: It is used in the production of parts that require fine and precise workmanship.

- Plate Rolling: It is a preferred metal forming method for bending large-scale and thick metal sheets.

Metal Sheet Forming Machines

In metalworking processes, sheet metal forming machines play a critical role. These machines perform high-precision operations simply and with high potential efficiency. They also contribute to industrial machinery production by producing metal parts in the desired shape and size.

- CNC Bending Machines: Used in precision bending operations with computer-aided control. It is especially preferred in the production of complex and detailed parts.

- Hydraulic Press Machines: It allows metals to be shaped by applying high pressure. It is an ideal option for processing heavy and thick metal parts.

- Roll Rolling Machines: Used for flattening and plate forming of metals. It offers high production speeds and continuous processing capability.

- 3 Roll Plate Sheet Metal Bending Machines: These machines allow sheet metal to be bent into the desired shape. It works with a three-roll hydraulic roller and is an ideal option for precise bending.

- 4 Roll Plate Sheet Metal Bending Machines: Ideal for making more complex and precise bends using four roller rolls. Especially useful for bending sheet metal with large dimensions.

- Roll Forming Machines: Used for forming metal sheets in a continuous process. It provides many advantages in terms of use in the manufacture of long parts.

- Laser Cutting Machines: Provides high precision in cutting metal sheets and allows complex shapes to be created easily.

- Hydraulic Guillotine Shears: Used for fast and smooth cutting of thick metal sheets.

Plate Bending and Production Process

Plate crimping is the process of shaping metal sheets by compressing them between rollers to achieve a certain thickness and flatness. In this process, metal sheets take their most technically perfect and smooth form. This method is widely preferred in large-scale production and in many sectors.

- Industry and Production: It is frequently preferred in the production of quality products thanks to its strength-enhancing feature in large-scale projects.

- Design and Aesthetics: It is a preferred method for aesthetic looks and special designs.

Strength and Metal

Strength is the resistance of any material against external factors. Strength, one of the most important properties of metals, makes them more resistant to various harsh conditions. High strength allows metals to be used in a wide range of applications.

- Heavy Industry: Machine parts and structural elements are expected to have high strength properties.

- Consumer Products: Ideal for producing durable and long-lasting products.

Conclusion

The industrial use of metals is a critical factor underpinning the modern world. Processes such as metal bending techniques, metal sheets and plate rolling increase productivity and durability in industry, while creating innovative solutions in various sectors. Metal sheet forming machines, as the most important tools in these processes, support the success in industrial production while optimizing production processes. SBFM Makine takes part in the production of many machines that will add value to businesses in this process. It offers ideal machine solutions for bending, crimping, pressing or flanging metal sheets into the desired shape.

You can contact SBFM Makine's sales support team about metal sheet bending machines and get information about the most suitable solutions for your business.