What are Hydraulic Press Machines?

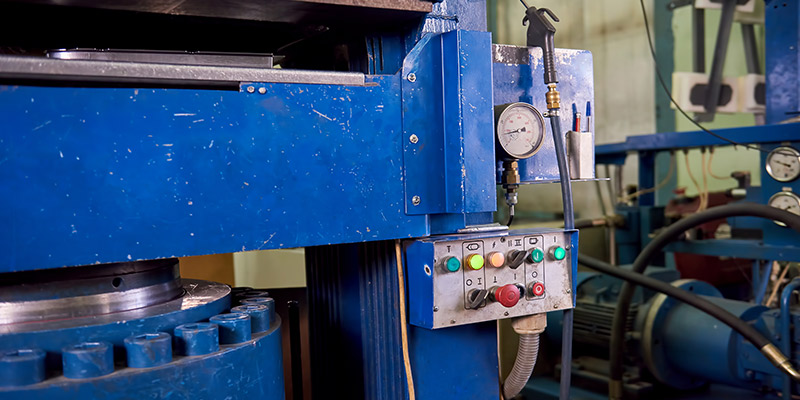

Hydraulic press machines are designed to perform many different operations during the industrial production stages. These machines usually move with the help of a hydraulic system and provide power transmission under high pressure using a liquid such as hydraulic oil. In short, with the help of hydraulic force, power is applied to the machine and the pressing process is performed.

Various industrial processes such as metal plate bending, cutting, punching, die forging, plastic injection molding are easily performed with hydraulic press machines. With these machines consisting of hydraulic cylinders, hydraulic cylindrical pressing process is performed and the required shape is obtained.

Hydraulic press machines have an important role in various processes that require high power and precision. These machines, which have a wide range of uses in terms of their working principle, advantages and activities in industry, are of absolute importance for the machinery industry.

The Functioning of Hydraulic Presses

Hydraulic presses are mainly based on the principle of a simple hydraulic system. In this system, the hydraulic cylinder and hydraulic fluid are included as the two main components that provide the function of the press. Pressure is generated by pumping hydraulic fluid, and this pressure performs the operation by the back-and-forth piston movement of the hydraulic cylinder. When the machine starts to work, the material to be processed is placed in the hydraulic press and compressed or shaped by the movement of the hydraulic cylinder. Thus, the hydraulic press machine completes its operation.

Advantages and Areas of Use

Hydraulic presses have a wide range of advantages. These advantages include features such as high power, precision, controllability and suitability for a wide range of workpieces. If we are going to materialize the advantages of hydraulic presses, which have a wide area widely used in industrial production;

- Application of Force: Hydraulic presses can apply a high percentage of force, which is effective for efficient processing of thick or durable materials.

- High Precision: Hydraulic systems provide precise control of force and movement, so that the material is processed accurately.

- Various Applications: Hydraulic presses are used in many versatile ways in many processes such as bending, cutting, punching, forming.

- Reliability and Durability: Hydraulic systems are resistant to long-term use. This provides cost savings while creating reliability in a sustainable production.

Features such as high power, precision, versatility and durability make hydraulic press machines the reason for preference. These machines have a wide range of uses in many sectors such as construction, defense and energy with various features such as metal forming, plastic injection molding, rubber molding, pressing, bending and cutting.

Its Role and Differences in the Industry

Hydraulic presses have an important role in the machinery industry. In the metal processing industry, they are used in processes such as sheet metal forming, metal cutting, bending and punching. In the automotive industry, it is often preferred for the construction of vehicle chassis and body parts. They are also widely used in fields such as plastic injection molding, rubber pressing and wood processing, and especially in industries such as metal processing, automotive, construction, packaging, furniture and electronics.

Working Process and Material Processing Advantages

The working process of hydraulic presses includes steps such as correct design, material selection and optimization of process parameters. Thus, productivity increases, material waste decreases and, as a result, processing costs decrease.

The material processing advantages of hydraulic presses include; powerful pressing process, possibility of precise control, high productivity, repeatable efficiency, low energy consumption and wide range of materials. Dec. Therefore, it is widely preferred in industrial production processes.

As a result;

Hydraulic presses are powerful machines that have an important role in industrial production processes. It has advantages such as high force application properties, high sensitivity, versatility and robustness. It provides high quality and cost savings while increasing the efficiency of production processes. The working principles and advantages are important factors that make these machines preferred in industrial use areas. Hydraulic press machines, when used correctly in accordance with their purpose, increase the production efficiency and the competitiveness of enterprises.